Providing Equipment And Engineering Services

For Industrial Process Plants since 1985

BOILERS & BOILER AUXILIARIES

- Fire Tube and Water Tube Boilers; Gas, Oil and Coal Fuels

- Boiler Rentals

- Economizers, Condensing Economizers, and Waste Heat Boilers

- Deaerators; Spray and Tray Types

- Burners, Burner Management & Combustion Controls

- Feedwater Heaters and Condensers

- Blowdown Heat Recovery Systems

- Boiler Water Treatment Equipment

SHELL AND TUBE HEAT EXCHANGERS

- Custom Designed Shell and Tube Exchangers Built to TEMA Standards

- Alloy Shell and Tube Exchangers

- Retubing and Rebuilding of Shell and Tube Heat Exchangers

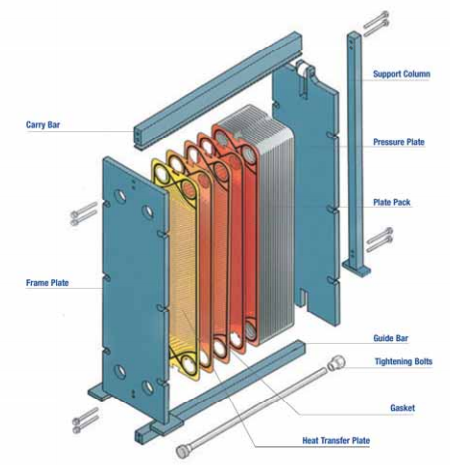

PLATE HEAT EXCHANGERS

- Plate and Frame Heat Exchangers

- Special Alloys and Gasket Materials

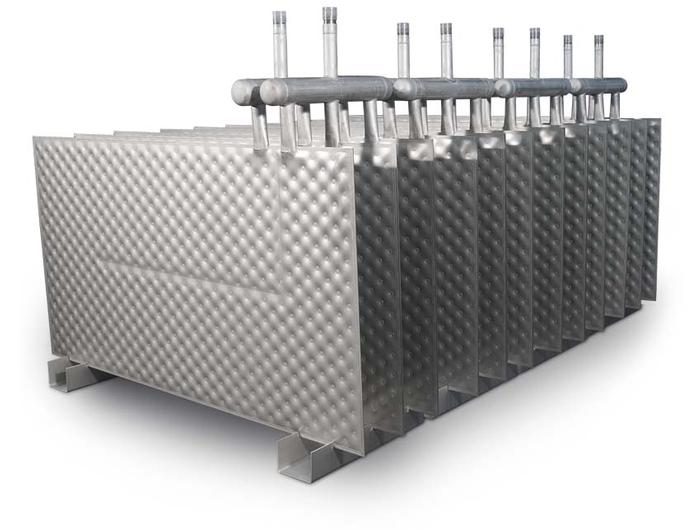

- Embossed Heat Transfer Panels, Clamp-On Panels, Immersion Panels, Integral Wall Panel Systems

PROCESS PRESSURE VESSELS

- ASME Code Pressure Vessel Fabrication

- High Pressure Vessels

- High Temperature Vessels

- Alloy Vessels

- Reactor Vessels

- Jacketed Vessels

WATER PURIFICATION SYSTEMS

- Water Softeners

- Reverse Osmosis Systems

- Ultra-Pure Water Systems

- Bulk Brinemaking Systems

- Water Filters

- Resin and Resin Removal Services

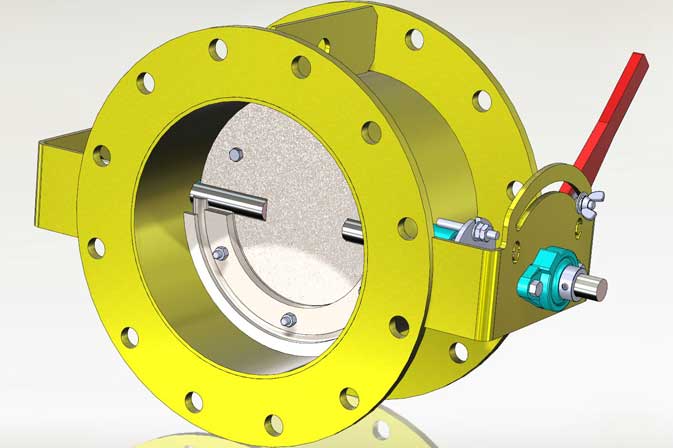

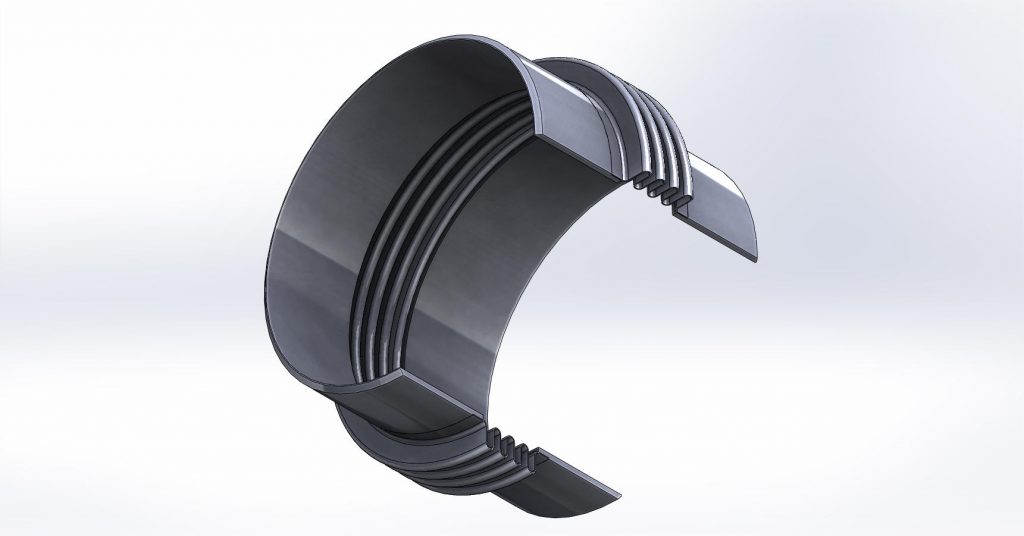

AIR AND FLUE GAS EQUIPMENT

- Industrial Dampers – Multilouver, Guillotine, Butterfly, Vortex, Zero Leakage, Diverter

- Expansion Joints – Composite Fabric, Metal bellows, High Pressure/Temperature

WHY PROTHERM?

TECHNICAL EXPERIENCE

Our employees have significant composite experience in the process industries as well as degrees in engineering and technical fields. Our President is a Registered Profesional Engineer and a licensed Stationary Engineer. We emphasize hands-on experience for our employees, and we have an ongoing training program to improve our product knowledge and application skills.

CUSTOMER COMMITMENT

We believe that our long term success at Protherm is measured by our contribution to increasing our customer’s profitability. Our goal is to be your preferred provider of engineered equipment systems, and we encourage your honest evaluation of our performance.

OPTIMUM DESIGN AND QUALITY FABRICATION

Our goal at Protherm is to provide our customers with sound technical assistance and high quality equipment systems which optimize safety, efficiency, cost, reliability, ease of operation and timely delivery. We visit each of our suppliers regularly to review their design and fabrication capabilities. We work constantly with our suppliers to tailor their products to meet your requirements and to transfer their designs into operating realities for you.

SYSTEMS ENGINEERING AND TURNKEY PROJECTS

When your plans call for an integrated system of equipment involving one or more of our products, Protherm’s project engineers are ready to serve you. We can efficiently design and assemble steam generation systems, water treatment systems, pressure and temperature control systems, process liquid pumping and storage systems, and flue gas systems. Our turnkey packages offer you single source responsibility from the planning phase through engineering, fabrication, installation, and startup.

Providing Process Equipment And

Engineering Services For Customers In:

- Chemical Plants

- Food Plants

- Beverage plants

- Dairies

- Pharmaceutical Plants

- Grain Processing

- Oil Refining

- Electronics Manufacturing

- Engineering Consultants

- Hospitals

- Universities

- Airports

- Ethanol Plants

- Power Utilities

- Automotive manufacturing

- Appliance Manufacturing

- Greenhouses

- Mechanical Contractors

For Your Next Process Systems Project Please Contact Us:

John Wiesehan

Sales Engineer, MSME

Registered P.E.

Licensed Stationary Engineer

Cell: 314-412-6720

jwiesehan@prothermcorp.com

Keri Dowell

Office Manager

kdowell@prothermcorp.com

Mike Braun

Sales Engineer

Licensed Stationary Engineer

Cell: 314-299-4929

mbraun@prothermcorp.com

Josh Cloyd

President, BSME

Registered P.E.

Cell: 314-287-2728

Josh@prothermcorp.com

PROTHERM CORPORATION

11108 South Towne Square

St. Louis, MO 63123

Phone: (314)-894-6720

Fax: (314)-892-0107